Industrial Zero Liquid Discharge Plants in Mumbai, India

Introduction to Zero Liquid Discharge (ZLD) in Mumbai, India

Mumbai stands as a prominent industrial powerhouse in India, nurturing sectors such as pharmaceuticals, textiles, chemicals, food and beverage, and petrochemicals. As these industries thrive, so does the concern surrounding environmental sustainability and water resource management. Regulatory authorities and growing ecological awareness have made it imperative for industries in Mumbai to adopt advanced wastewater treatment technologies. One of the most impactful and environmentally responsible solutions is the Zero Liquid Discharge (ZLD) system.

Aquacaresee Pvt. Ltd., a leader in water treatment innovation since 2006, is at the forefront of delivering effective and customized ZLD systems tailored for industrial needs in Mumbai. With over 18 years of experience, Aquacaresee has developed a legacy of reliability, offering comprehensive wastewater treatment solutions grounded in cutting-edge technology and a commitment to environmental stewardship.

Understanding the Concept of Zero Liquid Discharge (ZLD)

Zero Liquid Discharge is more than just a technological approach—it’s a philosophy centered around the idea of minimizing industrial impact on natural water bodies. The ZLD system operates on a closed-loop model, where no liquid waste is discharged into the environment. Instead, the system recovers and reuses water from wastewater streams, leaving behind only solid waste in the form of crystallized salts or dry sludge.

This advanced treatment process typically begins with a pre-treatment phase where large particles and impurities are removed. The water is then treated through reverse osmosis to eliminate dissolved solids. What remains is further concentrated through thermal processes like evaporation and crystallization. The end result is reusable water and non-hazardous solids, ensuring full compliance with environmental norms and contributing to a circular water economy.

The Need for ZLD in Mumbai’s Industrial Sector

Mumbai’s dense population and industrial intensity generate significant volumes of wastewater. The growing strain on freshwater resources, coupled with strict environmental regulations enforced by agencies like the Maharashtra Pollution Control Board (MPCB), necessitate sustainable wastewater management practices. ZLD systems provide a vital solution, enabling industries to not only meet compliance requirements but also reduce their water footprint significantly.

Incorporating ZLD systems allows companies to conserve water by recycling and reusing treated water within their own facilities. Moreover, this process eliminates the risk of environmental contamination, ensuring that no untreated effluent reaches rivers, lakes, or underground water reserves. For businesses, this means enhanced sustainability credentials, long-term cost savings on water procurement, and strengthened alignment with corporate social responsibility (CSR) initiatives.

Aquacaresee Pvt. Ltd.: Pioneers in ZLD Technology Since 2006

Founded in 2006, Aquacaresee Pvt. Ltd. has been instrumental in advancing wastewater treatment solutions across India. The company specializes in the design, engineering, manufacturing, and maintenance of industrial ZLD systems, with a strong focus on reliability, energy efficiency, and operational ease.

Over nearly two decades, Aquacaresee has implemented numerous turnkey projects for a wide array of industries in Mumbai. The company’s strength lies in its deep understanding of diverse industrial effluents and its ability to craft tailor-made solutions that cater to the specific needs of each client. With a fully equipped in-house research and development team, Aquacaresee ensures that its technologies remain on the cutting edge, continually evolving in line with environmental norms and client expectations.

Technologies Behind Aquacaresee’s ZLD Systems

Aquacaresee’s Zero Liquid Discharge plants combine multiple high-performance technologies into an integrated solution. At the heart of the system lies the Reverse Osmosis (RO) process, which significantly reduces the load of dissolved impurities. This is followed by thermal treatment techniques such as Multiple Effect Evaporation (MEE), where the remaining wastewater is further concentrated. In advanced stages, crystallization processes separate remaining solids, producing a solid cake that is easy to manage and dispose of safely.

To enhance energy efficiency and reduce operating costs, technologies like Thermal Vapor Recompression (TVR) are incorporated, allowing for the reuse of steam in evaporation cycles. Additionally, sophisticated sludge dewatering systems manage the solid waste, ensuring minimal volume and safe handling. Every component of the ZLD system is optimized for industrial scalability, operational longevity, and environmental compliance.

How Aquacaresee Executes ZLD Projects in Mumbai

Every ZLD project executed by Aquacaresee begins with a comprehensive feasibility study and site assessment. This initial phase ensures that the solution designed is technically and economically viable for the client. Based on this analysis, a customized treatment scheme is developed, incorporating the most suitable technologies and components.

Following the design phase, the system is meticulously engineered, fabricated, and installed on-site. Aquacaresee takes pride in its turnkey approach, which includes full system integration, testing, and commissioning. The final stage of the process involves training plant operators and providing them with the tools and knowledge necessary to run the system efficiently. Clients also benefit from ongoing technical support and preventive maintenance services, ensuring long-term performance and reliability.

Real-World Impact: Success Stories from Mumbai

Over the years, Aquacaresee has transformed the wastewater management practices of several industries in Mumbai. One such success story comes from a textile manufacturer in Navi Mumbai, where a 100 KLD ZLD plant was deployed. This system achieved a remarkable 92% water recovery rate, saving the client nearly 1.2 million liters of water per month. Another prominent case involved a pharmaceutical plant in Thane, where a highly specialized ZLD system was implemented to treat complex process wastewater, resulting in a 98% reduction in pollutants.

In Andheri, a food processing company turned to Aquacaresee for a custom ZLD solution that included advanced RO and crystallization units. The result was an 85% reduction in the facility’s overall water footprint, significantly enhancing its sustainability profile. These case studies not only highlight Aquacaresee’s technical expertise but also demonstrate the tangible benefits of adopting ZLD systems in real industrial environments.

Distinct Advantages of Partnering with Aquacaresee Pvt. Ltd.

Choosing Aquacaresee as a ZLD partner brings numerous benefits. The company has a proven track record of successfully delivering over 100 industrial ZLD installations, each tailored to meet stringent environmental standards and unique client requirements. Their facilities are ISO-certified, and their operational protocols ensure consistent quality, safety, and reliability.

With a local presence in Mumbai and a dedicated team of engineers, Aquacaresee provides prompt support and service. Their customer-centric approach is evident in the long-term relationships they maintain, offering everything from system upgrades to real-time monitoring and troubleshooting. Whether it’s a small manufacturing unit or a large industrial estate, Aquacaresee’s expertise scales to fit every project.

Client testimonials consistently highlight the company’s professionalism, technical excellence, and commitment to environmental goals. These endorsements serve as a testament to Aquacaresee’s credibility and the trust it has built within Mumbai’s industrial ecosystem.

Comprehensive Maintenance and Support Services

Aquacaresee’s relationship with its clients extends far beyond the commissioning of the plant. The company offers a wide range of after-sales services designed to ensure the uninterrupted functioning of ZLD systems. These services include routine maintenance checks, system diagnostics, remote monitoring, and immediate supply of critical spare parts. Furthermore, Aquacaresee continually evaluates system performance and suggests necessary upgrades to keep operations aligned with evolving environmental regulations and industry needs.

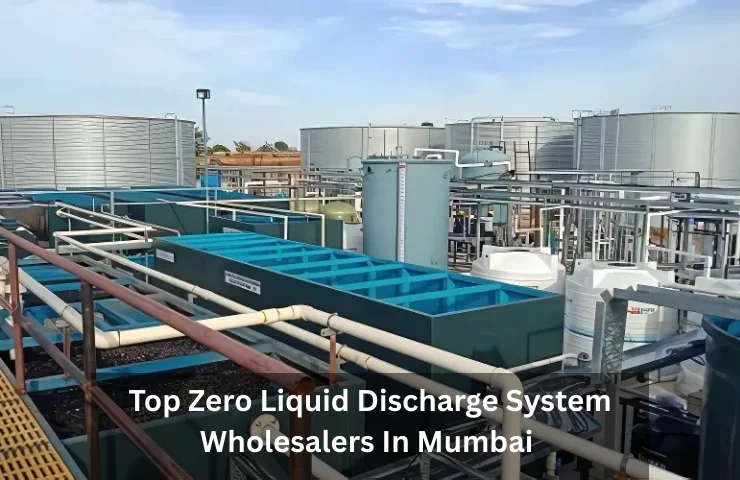

Visual Insights Into Our Work

Aquacaresee’s project portfolio is rich with successful installations across Mumbai. Visual documentation includes high-resolution images of full-scale ZLD plant setups in Navi Mumbai, showcasing the intricate design and layout of the treatment units. You can also view specialized components like multiple-effect evaporators in a Thane pharmaceutical plant and control panel interfaces used for real-time monitoring and system control. These images not only reflect our technological prowess but also our attention to operational aesthetics and user-friendliness.

Environmental Regulations Driving ZLD Adoption in Mumbai

Mumbai’s industrial zones are governed by a stringent set of environmental regulations established by entities such as the Maharashtra Pollution Control Board (MPCB), Central Pollution Control Board (CPCB), and National Green Tribunal (NGT). These authorities mandate strict compliance when it comes to the treatment and discharge of industrial effluent. The regulatory push for Zero Liquid Discharge is not merely a legal requirement but a call to action for responsible water stewardship. Aquacaresee Pvt. Ltd. plays a pivotal role in enabling industries to meet these benchmarks seamlessly, without compromising on operational efficiency or environmental ethics.

Economic and Operational Benefits of ZLD Implementation

While the initial investment in a ZLD system might seem substantial, the long-term economic advantages far outweigh the costs. Industries in Mumbai that have adopted ZLD systems by Aquacaresee report significant savings in water procurement costs, reduced environmental levies, and lowered operational risks. Additionally, the ability to recycle and reuse water reduces dependency on municipal or borewell sources—an important factor in water-stressed areas. Aquacaresee’s emphasis on energy-efficient designs and automation ensures optimal performance with minimal manual intervention, translating into lower manpower and maintenance overheads.

Future of Industrial Wastewater Management in Mumbai

As climate change accelerates and freshwater resources become increasingly scarce, the future of industrial operations in Mumbai will be heavily dependent on circular water technologies. The shift from traditional effluent discharge systems to closed-loop ZLD setups marks a significant evolution in industrial thinking. Companies are no longer merely reacting to regulations—they are proactively seeking sustainable models. Aquacaresee Pvt. Ltd., with its forward-looking research and agile engineering capabilities, is ideally positioned to lead this transition. Their systems are not only scalable and compliant but also adaptable to future technologies such as AI-based monitoring and predictive maintenance.

Contact Us

At Aquacaresee Pvt. Ltd., we are committed to providing high-quality wastewater treatment solutions tailored to your needs. If you have any questions or want to learn more about our services, please feel free to get in touch with us.

- Phone: + 91 – 96532 47121

- Email: marketing@aquacaresee.com

- Website: www.aquacaresee.com

Conclusion

In a city like Mumbai, where industrial growth and environmental responsibility must go hand in hand, Zero Liquid Discharge (ZLD) systems offer a practical and sustainable solution. They not only help industries meet the stringent regulations set by the Maharashtra Pollution Control Board (MPCB) but also drastically reduce dependence on freshwater resources by enabling internal water reuse and recycling.

Aquacaresee Pvt. Ltd., with over 18 years of experience in wastewater management and industrial ZLD solutions, has earned the trust of numerous clients across Mumbai’s pharmaceutical, textile, chemical, and food & beverage sectors. From concept to commissioning and long-term support, Aquacaresee delivers high-efficiency, tailor-made ZLD systems that ensure environmental compliance, operational savings, and a positive sustainability profile.

If your facility in Mumbai is looking to upgrade its wastewater treatment infrastructure, Aquacaresee is the go-to ZLD plant manufacturer for turnkey solutions that combine cutting-edge technology with unmatched reliability.