STP For Pharma Industries In Nashik

STP For Pharma Industries In Nashik.In Nashik’s booming pharmaceutical corridor, Sewage Treatment Plant (STP) systems play a critical role in ensuring compliance, sustainability, and operational efficiency. Aquacaresee Pvt. Ltd., established in 2006, brings over 18 years of expertise in designing, installing, and maintaining high-performance STP systems tailored for pharma industries. In this post, we’ll explore their core solutions—wastewater management, industrial purification, sustainable filtration—and explain why Aquacaresee stands out as Nashik’s trusted partner.

Why Pharma Companies Need Robust STP Systems

Regulatory Compliance & Environmental Responsibility

Pharmaceutical facilities generate wastewater containing high COD, BOD, TSS, solvents, and chemicals. Efficient STP systems ensure treated effluent meets MPCB, CPCB norms, protecting local ecosystems and avoiding legal penalties.

Water Reuse & Cost Efficiency:

Modern STPs help pharma plants recycle treated water for cooling towers, flushing, and utilities—reducing freshwater costs and boosting sustainability through circular water use.

Plant Reliability & Safety

Specialized biological and membrane treatments (e.g. MBR, SBR) control odors, sludge, and microbial growth—ensuring reliable operation without contamination risks.

Aquacaresee Pvt. Ltd.—Pharma STP Experts Since 2006

Proven Track Record (18+ Years)

Founded in 2006, Aquacaresee has delivered hundreds of successful STP and ETP projects across Nashik’s pharmaceutical, chemical, and industrial sectors. Their long industry presence reflects consistent performance and trust.

Tailored STP Technologies

- MBBR, SBR, MBR systems for high-removal efficiency

- Compact/modular packaged plants for pharma units with space constraints

- Automation & SCADA controls for remote monitoring and compliance

Full Lifecycle Support

Aquacaresee provides start-to-finish services including consulting, design, installation, commissioning, and annual maintenance contracts (AMC). Their in-house team ensures smooth integration and long-term reliability.

Core STP & Purification Solutions for Pharma Plants

Sewage Treatment Plants (STP)

- Capacities ranging from 100–10,000 m³/day per project

- Biological systems: activated sludge, extended aeration, MBR

- Tertiary treatment: sand filters, UV/Ozonation, polishing for reuse

Industrial Effluent Purification

- Multi-stage ETPs tailored to pharmaceutical effluents

- Reverse Osmosis (RO), ultrafiltration (UF), activated carbon filtration

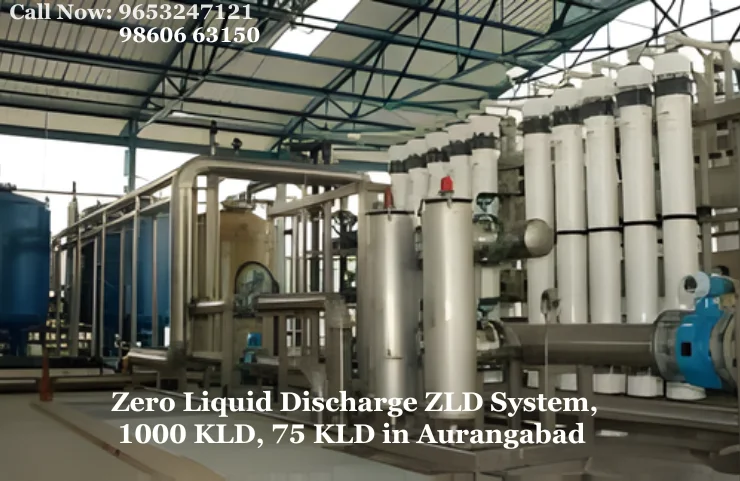

- Zero Liquid Discharge (ZLD) options for sensitive operations

Sustainable Filtration & Water Reuse

- Pressure sand filters, gravity filters, multimedia filters

- RO/UF systems for ultrapure water generation

- Demineralizers and greywater reuse modules integrated into STP/ETP setups.

Sustainability & Innovation at Aquacaresee

Zero-Liquid Discharge & Resource Recovery

Aquacaresee’s ZLD systems maximize water reuse and minimize environmental impact. Sludge is treated, dewatered, and possibly converted into biogas through methanation, aligning with circular economy principles.

Green Engineering & Energy Efficiency

Plants feature VFD blowers, solar compatibility, and low-sludge bioreactors, ensuring resource-efficient operations. Their designs support rainwater harvesting and constructed wetlands as part of wider sustainable infrastructure.

Choosing Aquacaresee: A Smart Pharma STP Investment

Technical Excellence

- 18+ years of application-specific engineering

- Compliance with CPCB/MPCB discharge standards

- SCADA-based monitoring and consistent process control

Cost Optimization & ROI

- Capital and operating expenditure planning

- Water reuse capability, energy savings, minimal sludge generation

- Typical ROI in 2–4 years through regulatory compliance and resource recovery

Local Expertise with Global Standards

Based in Nashik, they deeply understand local wastewater profiles and MPCB policies. Their solutions align with global best practices and certifications like ISO 9001.

Best Practices for Pharma STP Implementation

- Conduct site assessment (incoming loads, footprint, effluent quality)

- Choose appropriate technology (MBBR vs. MBR vs. SBR)

- Integrate automation—SCADA, remote monitoring, alerts

- Plan sludge management and potential resource recovery

- Provide operator training and AMC for smooth operations

Understanding Pharma Wastewater Composition

Pharmaceutical effluent isn’t ordinary sewage. It contains high COD, BOD, APIs (active pharmaceutical ingredients), solvents, salts, and microbial loads. This makes advanced STP solutions in Nashik essential for safe discharge or reuse. Aquacaresee conducts thorough wastewater analysis to select the right treatment technology that protects both the environment and production integrity.

Importance of Pretreatment in Pharmaceutical STPs

Before reaching the biological stage, wastewater from pharma industries must undergo pretreatment. This may include oil & grease removal, pH neutralization, equalization tanks, and screening. Aquacaresee designs robust pretreatment modules to ensure downstream biological systems are protected and efficient.

Industrial RO Systems for Final Water Polishing

To meet stringent pharma discharge norms—or for water reuse—many plants need a Reverse Osmosis (RO) system after STP. Aquacaresee offers fully integrated RO units with high rejection rates, membrane cleaning systems, and low energy consumption, making it perfect for pharma water recycling in Nashik.

Sludge Management and Dewatering Systems

An often-overlooked element of STP design is sludge handling. Aquacaresee uses sludge drying beds, filter presses, or centrifuges based on volume and plant size. Sludge can be composted, incinerated, or safely disposed of through authorized agencies—keeping the plant clean and compliant.

SCADA and IoT-Based Automation

Modern STPs aren’t just mechanical—they’re smart. Aquacaresee integrates SCADA and IoT sensors to monitor flow rates, BOD/COD levels, tank levels, and system health in real time. Alerts and reports are accessible remotely, reducing downtime and ensuring compliance with pharma wastewater standards.

AMC & Remote Support Services

Post-installation, many pharma clients rely on Aquacaresee’s Annual Maintenance Contracts (AMC). This ensures regular servicing, biological health checks, emergency support, and preventive maintenance. Their dedicated Nashik service team provides 24/7 support, which is crucial for regulated industries like pharma.

Frequently Asked Questions (FAQ)

Q1. What is an STP and why is it important for pharmaceutical industries in Nashik?

Ans: An STP, or Sewage Treatment Plant, is essential for treating wastewater generated by pharma industries. In Nashik’s growing pharmaceutical hub, strict MPCB and CPCB norms make STPs necessary to manage high loads of organic and chemical waste, prevent pollution, and enable water reuse.

Q2. What type of STP is best suited for pharma effluent?

Ans: Membrane Bioreactor (MBR) and Moving Bed Biofilm Reactor (MBBR) technologies are widely used due to their efficiency in handling high COD/BOD levels and producing reusable water. Aquacaresee customizes solutions based on the pharma plant’s effluent profile and space availability.

Q3. How much space is required for setting up an STP in a pharmaceutical facility?

Ans: Space depends on flow rate, chosen technology, and layout. Aquacaresee offers compact modular STPs ideal for pharma industries with space constraints, without compromising on output quality or compliance.

Q4. Can treated water from an STP be reused in pharmaceutical operations?

Ans: Yes. Treated water from STPs can be reused in non-potable applications such as cooling towers, gardening, utility cleaning, or flushing. Advanced polishing through RO or UV ensures safety and efficiency, significantly reducing freshwater dependency.

Q5. What makes Aquacaresee a reliable STP provider for pharma industries?

Ans: Aquacaresee Pvt. Ltd. brings 18+ years of experience in water treatment, with deep expertise in pharma-specific wastewater challenges. They offer complete end-to-end solutions—from design and installation to automation, AMC, and regulatory support—all with strong local service presence in Nashik.

Get a Free Consultation from Aquacaresee

- Phone:+ 91 – 96532 47121 / + 91 – 98606 63150

- Email: marketing@aquacaresee.com

- Website: www.aquacaresee.com

Conclusion

In today’s pharmaceutical landscape, managing wastewater responsibly is no longer optional—it’s essential. With strict environmental regulations and rising sustainability demands, having a reliable, efficient, and compliant STP for pharma industries in Nashik is critical. That’s where Aquacaresee Pvt. Ltd. shines. With over 18 years of proven experience since 2006, they deliver tailor-made STP solutions backed by robust engineering, cutting-edge technology, and strong local service. Whether you’re planning a new facility or upgrading your existing setup, Aquacaresee offers everything from design to AMC—ensuring performance, compliance, and long-term value. Choose a partner who understands your industry, meets your regulatory needs, and supports your sustainability goals. Choose Aquacaresee—where clean water meets clean compliance.