Effluent Treatment Plant For Factories In Nashik, India

What is an Effluent Treatment Plant (ETP)?

Effluent Treatment Plant For Factories In Nashik, India is a crucial infrastructure used to treat industrial wastewater before it is released into the environment. Factories often generate a wide variety of pollutants chemicals, oils, toxins, heavy metals, and other contaminants. ETPs help in purifying this water, making it reusable or safe for discharge. With pollution levels rising and environmental regulations tightening, ETPs are no longer optional they’re essential.

Why ETPs Are Crucial for Factories in India

India, being one of the world’s leading manufacturing hubs, is also one of the largest producers of industrial wastewater. With stricter Central and State Pollution Control Board (CPCB & SPCB) norms, businesses must ensure compliance. Installing an efficient ETP not only safeguards the environment but also boosts a company’s green credentials, lowers operational costs, and ensures regulatory peace of mind.

The Growing Need for Effluent Treatment in Nashik

Industrial Boom in Nashik

Nashik, once known for agriculture and wine, has rapidly evolved into a bustling industrial hub. From MIDC areas like Satpur and Ambad to newer zones in Sinnar and Igatpuri, Nashik is home to diverse industries pharmaceuticals, textiles, automotive, and engineering units. With this growth, the volume of wastewater has also surged.

Environmental Challenges Due to Industrial Waste

Unchecked industrial discharge has a domino effect polluted rivers, soil contamination, and groundwater depletion. The Godavari River, which flows through Nashik, has suffered from increasing waste loads. Factories must adopt sustainable practices to protect this lifeline and that’s where ETPs step in as saviors.

About Aquacaresee Pvt. Ltd.

Company Overview

Aquacaresee Pvt. Ltd., established in 2006, is a pioneer in industrial and commercial water treatment solutions in India. With headquarters in Maharashtra, the company has catered to over 500+ clients across sectors, delivering reliable and eco-friendly ETP systems.

18+ Years of Water Treatment Expertise

From manual systems in the early 2000s to modern IoT-enabled ETPs today, Aquacaresee has evolved with technology. Their 18+ years of experience bring unmatched technical proficiency, customer-centric innovation, and regulatory compliance expertise.

Effluent Treatment Plant For Factories In Nashik, India

Driven by the mission to “Recycle Every Drop,” the company is focused on:

- Water conservation

- Pollution control

- Cost-effective engineering

- Long-term environmental sustainability

Key Features of Aquacaresee ETP Solutions

Custom-Built Systems for Industries

Every factory is unique and so is its effluent. Aquacaresee offers tailor-made ETPs that align with your specific needs and industry effluent characteristics.

Energy-Efficient Design

Power consumption is a major cost concern for industries. Aquacaresee designs low-energy systems that reduce electricity use by up to 30% compared to conventional models.

Automated Operation & Monitoring

Using SCADA and IoT, you can monitor and control the ETP remotely. This leads to better efficiency, less human error, and real-time alerts.

Space-Saving Designs for Compact Areas

Even if your factory has limited space, Aquacaresee ensures the ETP fits without compromising performance.

Services Offered by Aquacaresee Pvt. Ltd.

Wastewater Treatment Plants (WWTP)

Ideal for industries generating high volumes of liquid waste. These plants treat sewage, grey water, and chemical effluents.

Industrial Water Purification Systems

Catering to process industries where ultra-clean water is a must. Includes deionization, filtration, and sterilization.

Reverse Osmosis (RO) Systems

Perfect for purifying water with high TDS levels. RO systems are designed for reuse and recycling.

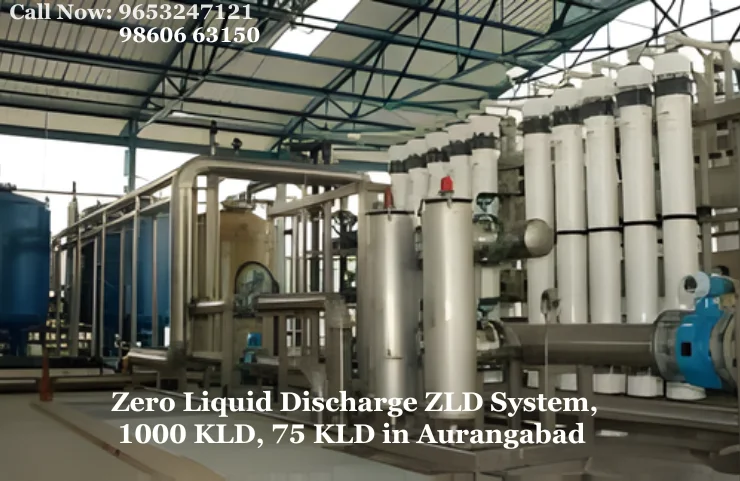

Zero Liquid Discharge Systems (ZLD)

Want to reuse 100% of your water? ZLD systems eliminate discharge, ensuring full water recovery and environmental compliance.

Sludge Dewatering & Disposal Units

Sludge management is critical. Aquacaresee offers filter presses, decanter centrifuges, and drying beds to manage sludge efficiently.

Why Factories in Nashik Should Choose Aquacaresee

- 18+ Years of Experience

- Over 500 Successful Installations

- Locally Based Service Teams

- In-House R&D

- High ROI and Low Maintenance

- Annual Maintenance Contracts (AMC)

Industries Benefiting from ETPs in Nashik

- Pharmaceuticals

Heavy use of solvents and chemicals demands efficient effluent treatment. - Food & Beverage

Wastewater from cleaning, processing, and packaging must be treated before discharge. - Chemicals & Dyes

High toxicity levels and pH fluctuations require advanced ETPs. - Textiles & Dyeing Units

Color removal, pH balancing, and chemical neutralization are must-haves. - Automobile & Engineering

Oily waste, metal particles, and coolants need thorough filtration.

Components of an ETP System

- Screening

- Oil & grease traps

- Sedimentation tanks

- Aeration tanks

- Activated sludge process

- Biological reactors

Tertiary Treatment

- Filtration

- Disinfection (UV/Chlorination)

- Reverse Osmosis

Sludge Handling

- Sludge digester

- Dewatering units

- Sludge drying beds

Working Process of Aquacaresee ETPs

- Collection – Effluents are gathered into equalization tanks.

- Screening – Solids and debris are filtered.

- Primary Clarification – Settles out heavy particles.

- Aeration – Injects oxygen to encourage microbial action.

- Secondary Clarification – Removes remaining suspended solids.

- Tertiary Treatment – Polishes the water using advanced filters.

- Discharge or Reuse – Final water is either discharged or recycled.

Importance of Sustainable Water Management

Eco-Friendly Solutions with Long-Term Impact

- Reduce freshwater demand

- Lower environmental pollution

- Encourage water reuse

- Preserve river and groundwater health

Legal Compliance & Government Norms

Aquacaresee ensures all installations are compliant with:

- CPCB (Central Pollution Control Board)

- MPCB (Maharashtra Pollution Control Board)

- GPCB, SPCB, and ISO 14001 standards

- Hefty fines

- Factory shutdown

- Legal actions

Failure to install an ETP can lead to:

Frequently Asked Questions (FAQ)

Q1.What is the average cost of an ETP in Nashik?

Ans: The cost varies by capacity and design but generally ranges from ₹5 lakh to ₹50 lakh for industrial setups.

Q2.Is ETP mandatory for small-scale industries?

Ans: Yes, as per CPCB norms, all industries discharging wastewater must install ETPs.

Q3.How long does installation take?

Ans: Typically, it takes 45–90 days depending on the size and complexity.

Q4.What maintenance is required?

Ans: Regular filter cleaning, pump checks, and periodic AMC from Aquacaresee ensure smooth performance.

5.Does Aquacaresee provide remote monitoring?

Ans: Yes, advanced ETPs from Aquacaresee include IoT-based real-time monitoring.

Get a Free Consultation from Aquacaresee

- Phone:+ 91 – 96532 47121 / + 91 – 98606 63150

- Email: marketing@aquacaresee.com

- Website: www.aquacaresee.com

Conclusion

If you’re a factory owner in Nashik, installing an Effluent Treatment Plant (ETP) is more than just meeting pollution control norms it’s a commitment to environmental sustainability and responsible manufacturing. With Aquacaresee Pvt. Ltd., you gain the advantage of over 18 years of proven expertise in water and wastewater treatment solutions. Our ETP systems are built with advanced, energy-efficient technology that ensures your industrial discharge meets the strictest regulatory standards. From consultation to commissioning and post-installation support, we provide end-to-end solutions tailored to your industry. Don’t wait for a legal notice or shutdown order from the pollution control board. Take proactive action today with Aquacaresee because cleaner operations mean a cleaner future for all. Partner with Nashik’s most trusted name in effluent treatment and lead the way toward a greener tomorrow.