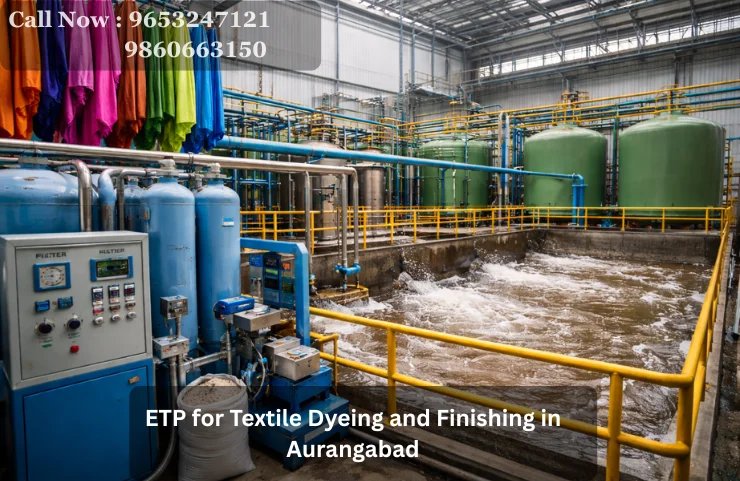

ETP for Textile Dyeing and Finishing in Aurangabad

ETP for Textile Dyeing and Finishing in Aurangabad : Complete Industrial Wastewater Treatment Solutions by Aquacaresee Pvt Ltd

Water is the lifeline of the textile dyeing and finishing industry but it’s also one of its biggest challenges. With increasing environmental regulations and rising water scarcity, having a reliable ETP for Textile Dyeing and Finishing in Aurangabad is no longer optional; it’s essential. That’s exactly where Aquacaresee Pvt Ltd steps in as a trusted and experienced partner.

Established in 2006, with 20+ years of industry experience, Aquacaresee Pvt Ltd specializes in the design, manufacturing, supply, installation, commissioning, and maintenance of water and wastewater treatment systems. Based in Pune, we serve industries across Aurangabad and Maharashtra, delivering customized, compliant, and future-ready ETP solutions.

ETP for Textile Dyeing and Finishing in Aurangabad

Introduction to Aquacaresee Pvt Ltd

Aquacaresee Pvt Ltd is not just another water treatment company it’s a solution-driven organization built on engineering excellence, real-world experience, and long-term trust. Since 2006, we have helped industries manage wastewater responsibly while improving operational efficiency and sustainability.From textile dyeing units to large-scale manufacturing plants, healthcare facilities, hospitality projects, agricultural operations, and municipal bodies, our solutions are designed to adapt, perform, and comply.

Why Textile Dyeing and Finishing Units Need Advanced ETP Systems

Textile dyeing and finishing processes generate wastewater loaded with:

- High color concentration

- Chemical residues

- Salts, surfactants, and heavy metals

- High BOD, COD, and TDS

Discharging this untreated wastewater is harmful not just to the environment but also to business continuity. Regulatory penalties, water shortages, and reputational risks make ETP installation a business-critical investment.

Think of an ETP like a filtration system for your industry’s conscience it cleans, restores, and protects.

WWTP for Construction Industry Wastewater in Aurangabad

Understanding Effluent Treatment Plants (ETP)

What is an ETP and How It Works

An Effluent Treatment Plant (ETP) treats industrial wastewater by removing physical, chemical, and biological contaminants so that the water can be safely discharged or reused. For textile dyeing and finishing units, ETPs are designed to handle complex effluents with varying loads and compositions.

Common Pollutants in Textile Dyeing & Finishing Wastewater

- Reactive dyes and pigments

- Acids and alkalis

- Sodium chloride and sodium sulfate

- Suspended solids and organic matter

Environmental Impact of Untreated Textile Effluent

Untreated effluent can contaminate soil, groundwater, and surface water bodies, affecting agriculture, drinking water, and public health. A well-designed ETP prevents this damage while ensuring regulatory compliance.

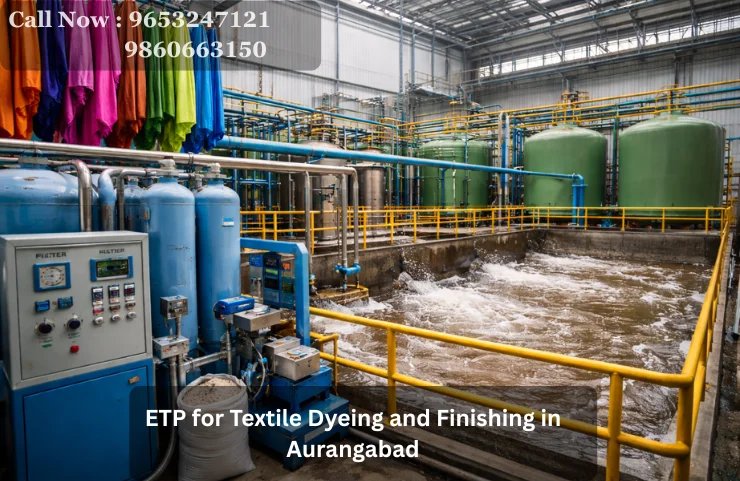

Complete Range of Services Offered by Aquacaresee Pvt Ltd

- ETP Design, Manufacturing & Supply

Engineered systems built for efficiency, durability, and compliance. - Turnkey Projects

From concept to commissioning we handle everything. - Consultancy Services

Process audits, feasibility studies, and regulatory guidance. - Installation & Commissioning

Precision execution with minimal downtime. - Annual Maintenance Contracts (AMC)

Ensuring consistent performance and peace of mind. - Operation & Process Maintenance (O&M)

Let our experts manage your ETP while you focus on production.

ETP Treatment Process for Textile Dyeing and Finishing Industry

- Primary Treatment

Removal of large solids, grit, and initial color reduction. - Secondary Biological Treatment

Breakdown of organic matter using aerobic or anaerobic processes. - Tertiary & Advanced Treatment

Color removal, filtration, and polishing using advanced technologies. - Sludge Handling & Disposal

Efficient sludge dewatering and compliant disposal methods.

ETP for Textile Dyeing and Finishing in Aurangabad

Aurangabad is a growing textile and manufacturing hub. With this growth comes responsibility. Textile units in the region must comply with MPCB and CPCB norms, making advanced ETP systems a necessity rather than a luxury. Aquacaresee Pvt Ltd delivers ETP solutions specifically engineered for Aurangabad’s textile dyeing and finishing industry, considering:

- Local water characteristics

- Regulatory discharge limits

- Space and operational constraints

Local Environmental Regulations and Compliance

MPCB & CPCB Guidelines for Textile ETPs

- Discharge standards for BOD, COD, TSS, color, and pH

- Reuse and recycling norms

- Sludge handling and disposal regulations

Zero Liquid Discharge (ZLD) Readiness

Our ETPs can be upgraded to ZLD systems, enabling complete water recovery and zero wastewater discharge.

Aquacaresee Pvt Ltd : 20+ Years of Experience in Water & Wastewater Treatment

Experience matters especially in complex industries like textiles. With two decades of hands-on expertise, Aquacaresee Pvt Ltd brings:

- Proven engineering practices

- In-depth process understanding

- Long-term operational insights

In-House Design & Manufacturing Expertise

Unlike generic suppliers, we design and manufacture systems in-house, ensuring quality, performance, and accountability.

Customized ETP Solutions for Textile Dyeing & Finishing Units

Unlike generic suppliers, we design and manufacture systems in-house, ensuring quality, performance, and accountability.

- Effluent characteristics

- Production capacity

- Compliance goals

- Budget and lifecycle cost

Why Choose Aquacaresee Pvt Ltd for ETP in Aurangabad

- Experience & Expertise

20+ years of proven results. - Authoritativeness

Trusted by industries across Maharashtra. - Trust & Transparency

Long-term relationships built on performance and support. - Energy-Efficient & Cost-Effective Systems

Optimized designs that reduce operational costs.

Benefits of Installing an ETP for Textile Dyeing and Finishing:

- Regulatory compliance

- Reduced water consumption

- Lower freshwater dependency

- Improved brand reputation

- Sustainable operations

Frequently Asked Questions (FAQs) :

Q1. What capacity ETP is suitable for textile dyeing units?

Ans: It depends on wastewater volume and effluent characteristics. Aquacaresee provides customized capacity planning.

Q2.Does Aquacaresee provide turnkey ETP projects?

Ans: Yes, we offer complete turnkey ETP solutions from design to commissioning.

Q3.Is AMC and O&M service available after installation?

Ans: Absolutely. We provide AMC and full O&M services.

Q4.Can treated water be reused in textile processes?

Ans: Yes, treated water can be reused for washing, cooling, and utilities.

Q5. How long does it take to install an ETP?

Ans: Typically 8–16 weeks, depending on plant capacity and scope.

Get a Free Consultation from Aquacaresee

- Phone:+ 91 – 96532 47121 / + 91 – 98606 63150

- Email: marketing@aquacaresee.com

- Website: www.aquacaresee.com

WWTP for Construction Industry Wastewater in Aurangabad

Conclusion

Choosing the right ETP for Textile Dyeing and Finishing in Aurangabad is about more than compliance—it’s about sustainability, efficiency, and future growth. With Aquacaresee Pvt Ltd, you gain a partner backed by 20+ years of experience, technical expertise, and a commitment to long-term success. From design to O&M, we deliver solutions that work today and tomorrow.

Call Now: 9653247121

“Don’t forget to share this post!”