ETP For Food Processing Industries In Nashik

What Is an ETP?

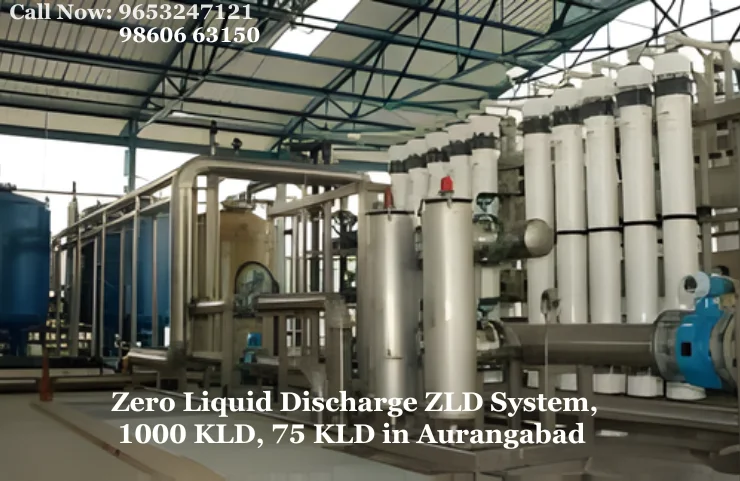

ETP for Food Processing Industries in Nashik plays a vital role in ensuring sustainable and compliant wastewater management. An Effluent Treatment Plant (ETP) is a specialized facility designed to treat industrial wastewater, removing harmful contaminants before it is discharged or reused. In the food processing industry, where large volumes of water are used in cleaning, processing, and packaging, the generation of wastewater containing organic and inorganic pollutants is inevitable. A well-designed ETP for food processing industries in Nashik helps control these pollutants, ensuring compliance with CPCB and MPCB environmental norms. It not only protects local ecosystems but also supports water recycling and cost savings for manufacturers. By implementing advanced technologies such as MBR, UF, and ZLD, industries can enhance their sustainability goals while meeting legal obligations. Choosing a trusted provider like Aquacaresee ensures your ETP is efficient, durable, and tailored to your specific process needs.

Why Are ETPs Crucial for Food Processing Units?

Imagine preparing tons of processed food each day — all that cleaning, boiling, and chemical processing generates a lot of wastewater. Without proper treatment, this water can damage aquatic life, soil quality, and even groundwater reserves. ETPs act like guardians of nature, cleansing harmful elements before the water re-enters the ecosystem.

The Legal and Environmental Compliance Perspective

The Central Pollution Control Board (CPCB) and Maharashtra Pollution Control Board (MPCB) mandate strict effluent discharge norms. Non-compliance can lead to hefty fines and even shutdowns. With an efficient ETP setup from Aquacaresee Pvt. Ltd., industries can rest easy knowing they are on the right side of the law — and the planet.

Overview of Aquacaresee Pvt. Ltd.

Company Background – 18+ Years of Excellence

Established in 2006, Aquacaresee Pvt. Ltd. has carved a niche in the water treatment sector. With more than 18 years of domain expertise, the company has emerged as a leader in designing and commissioning customized ETPs for diverse industries across India, especially in Maharashtra and Nashik.

Vision, Mission, and Sustainability Commitment

Aquacaresee’s vision is simple — “Water Sustainability for a Better Tomorrow.” Their mission includes delivering innovative, cost-effective, and eco-friendly treatment solutions that empower industries to minimize their environmental impact.

Service Footprint Across India and Nashik

While their headquarters are in Maharashtra, Aquacaresee’s reputation spans across India. In Nashik, they’ve become the go-to name for food processing units in need of reliable effluent treatment solutions. Their localized support, faster delivery, and strong network make them an ideal partner.

Importance of ETPs in Food Processing Industries

Food industries generate a wide range of effluents, including:

- Organic waste from washing raw materials

- Oils and fats from processing units

- Chemicals used in preservation

- Cleaning and sanitization residues

Each of these pollutants can create environmental hazards if left untreated.

Impact on Local Ecosystems

Improperly discharged effluents can:

- Contaminate water bodies

- Harm aquatic life

- Pollute soil and reduce fertility

- Affect public health through waterborne diseases

How Aquacaresee Designs Tailor-Made ETPs for Food Industries

Site Survey and Custom PlanningZLD wherever required.

No two industries are the same. Aquacaresee begins every project with an in-depth site assessment. They study:

- Type and volume of wastewater

- Available space

- Discharge location and reuse potential

Technology Used in ETPs

Aquacaresee integrates the latest in:

- MBR (Membrane Bioreactor)

- SBR (Sequencing Batch Reactor)

- DAF (Dissolved Air Flotation)

- MBBR (Moving Bed Biofilm Reactor)

These technologies ensure maximum treatment efficiency with minimal space and energy consumption.

Modular and Scalable Design Approach

As your food plant grows, your ETP should too. Aquacaresee designs systems that are modular — meaning they can be upgraded or expanded with ease. Whether you’re a small dairy unit or a large frozen food plant, they’ve got you covered.

Core Features of Aquacaresee ETP Systems

Biological and Chemical Treatment Integration

Combining physical, chemical, and biological stages allows for:

- Breakdown of organic matter

- Removal of fats, oils, and grease (FOG)

- Neutralization of pH levels

Sludge Handling and Odor Control

No one likes foul smells near a food facility. Aquacaresee integrates odor-control systems and effective sludge management tools like filter presses and sludge dryers, ensuring a clean, healthy workplace.

Energy-Efficient and Low-Maintenance Designs

With high-efficiency motors, smart sensors, and automated panels, Aquacaresee ETPs run smoothly with minimal human intervention and lower operational costs.

Benefits of Partnering with Aquacaresee Pvt. Ltd.

- Custom Engineering with Cost Efficiency

Their in-house R&D ensures every ETP is optimized for performance and cost, avoiding overdesign or underperformance. - Reliable AMC and After-Sales Service

24×7 helpline, periodic maintenance, and on-call technician support make sure your ETP never fails when you need it the most. - Remote Monitoring and Digital Control Options

Smart dashboards and IoT-enabled panels allow you to track and control ETP performance in real time — even from your mobile.

Frequently Asked Questions (FAQ) :

Q1.What types of food processing units need an ETP?

Ans: Almost all types — including dairy plants, fruit & vegetable processors, beverage units, meat processing, and bakeries — need an ETP due to the high organic and chemical load in their wastewater.

Q2.How much space does an ETP require?

Ans: The space depends on the volume of wastewater and the treatment technology used. Aquacaresee offers modular systems that can fit even in compact industrial areas.

Q3.What certifications are needed for ETP compliance?

Ans: Industries must comply with CPCB, MPCB, and ISO standards. Aquacaresee ensures all installations meet or exceed these requirements.

Q4.How does Aquacaresee ensure minimal operational cost?

Ans: By using energy-efficient components, automation, and optimized treatment processes, Aquacaresee minimizes power usage and chemical consumption, reducing overall costs.

Q5.Can treated water be reused within the plant?

Ans: Yes! Treated water can be used for non-potable purposes like gardening, cleaning, cooling towers, and flushing — contributing to water conservation and cost savings.

Get a Free Consultation from Aquacaresee

- Phone:+ 91 – 96532 47121 / + 91 – 98606 63150

- Email: marketing@aquacaresee.com

- Website: www.aquacaresee.com

Conclusion: Why Choose Aquacaresee Pvt. Ltd. for ETP in Nashik

In the thriving food processing sector of Nashik, effective wastewater management is not just about meeting environmental regulations—it’s a vital part of sustainable and responsible business operations. As the industry grows and faces increasing scrutiny over water usage and effluent discharge, having a reliable and efficient Effluent Treatment Plant (ETP) becomes crucial. Food industries generate high volumes of organic waste and complex effluents that, if left untreated, can harm the environment and public health. That’s why choosing the right ETP solution is essential for long-term operational efficiency, compliance with CPCB and MPCB norms, and safeguarding natural resources. Partnering with a trusted expert like Aquacaresee Pvt. Ltd., with over 18 years of industry experience, ensures your facility is equipped with a customized, high-performing, and eco-friendly treatment system tailored to your specific needs.