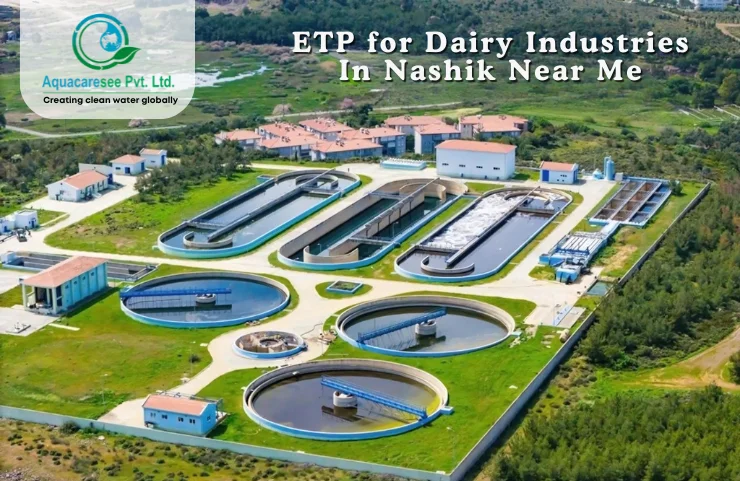

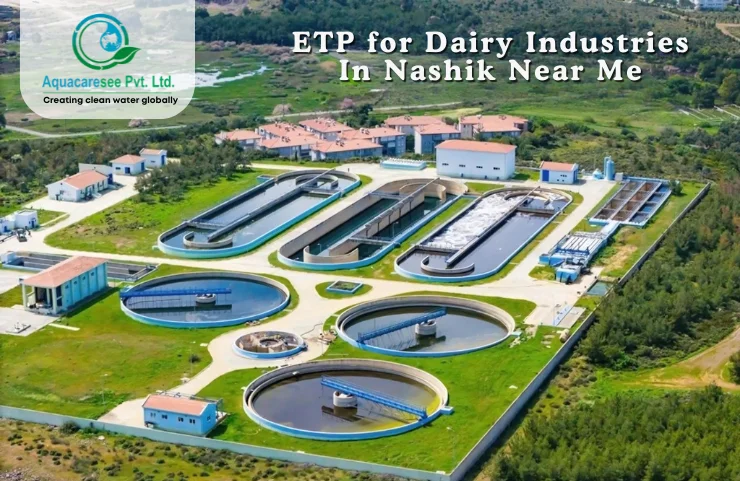

ETP for Dairy Industries In Nashik Near Me

Understanding the Need for ETP in Dairy Plants

Ever wondered where all the wastewater from milk processing goes? Dairy industries generate a significant amount of high-strength organic waste. think of milk spillage, washing water, cream, and fats. This untreated wastewater can severely pollute nearby water bodies and land, causing major environmental damage.That’s where Effluent Treatment Plants (ETPs) come in. They ensure that every drop of waste leaving a dairy unit is treated and safe for discharge or even reuse.

Overview of Nashik’s Dairy Industry Landscape

Nashik is rapidly emerging as a major agro-processing and dairy hub in Maharashtra. With a growing number of small, medium, and large-scale dairy plants, the need for reliable wastewater management systems is more urgent than ever.

About Aquacaresee Pvt. Ltd.

A Legacy Since 2006 – 18+ Years of Expertise

Established in 2006, Aquacaresee Pvt. Ltd. has been at the forefront of wastewater treatment and environmental engineering in India. With over 18 years of hands-on experience, they’ve delivered sustainable ETP solutions for various industries.dairy being a major focus.

Mission & Vision in Environmental Sustainability

Aquacaresee’s mission is simple but powerful: “Clean water for a better tomorrow.” Their vision revolves around sustainable, energy-efficient, and regulation-compliant treatment systems that support India’s green goals.

Importance of ETP in Dairy Industries

Environmental Regulations & Compliance

Pollution control boards across India mandate strict norms for wastewater discharge. Violating these can lead to hefty fines or shutdown notices. Installing a certified ETP helps dairy units stay compliant with:

- CPCB and SPCB discharge standards

- Zero Liquid Discharge (ZLD) targets

- ISO 14001 environmental guidelines

Reducing Environmental Footprint

An ETP doesn’t just filter wastewater. it reduces your plant’s carbon and ecological footprint. With water recycling technologies integrated, you can reuse up to 85% of treated water, drastically reducing your dependency on freshwater.

Protecting Water Bodies & Soil Health

Untreated dairy effluents are high in Biochemical Oxygen Demand (BOD) and Chemical Oxygen Demand (COD).both toxic to aquatic life. By treating this waste, ETPs preserve local water bodies, underground water tables, and soil fertility.

Components of an Efficient ETP Plant

This is where larger solids and fats are separated from wastewater using:

- Screens and grit chambers

- Oil & grease traps

- Equalization tanks

Secondary Treatment

This biological phase involves bacteria breaking down organic matter using methods like:

- Aeration tanks

- Trickling filters

- MBBR systems

Tertiary Treatment

The final polish of the water! Technologies like:

- Sand filtration

- Activated carbon filters

- UV and chlorination systems

ensure water is safe for reuse or discharge.

Sludge Management Systems

ETPs generate sludge that needs separate handling. Aquacaresee offers:

- Sludge drying beds

- Decanter centrifuges

- Filter press systems

Why Choose Aquacaresee for Your Dairy ETP Needs?

Custom-Built Solutions

No two dairy plants are the same. Aquacaresee’s ETPs are tailored to your specific load, space, and budget. That means better efficiency and less wastage.

High-Efficiency & Cost-Effective Systems

With modular design, energy-efficient motors, and low chemical consumption, these plants lower your OPEX while ensuring compliance.

In-house R&D and Innovation

Aquacaresee isn’t just a service provider.they’re pioneers. With their own research division, they continually innovate for better sludge management, minimal energy use, and smart automation.

Strong After-Sales Support

From AMC contracts to emergency repairs, Aquacaresee ensures your ETP never sleeps. Their 24×7 service team across Maharashtra is always ready.

Technologies Used in Aquacaresee ETP Systems

MBBR (Moving Bed Biofilm Reactor)

Ideal for space-constrained dairy units, MBBR is a compact and high-load-bearing biological treatment system.

SBR (Sequential Batch Reactor)

Perfect for batch-wise effluent discharge, especially useful in seasonal milk collection units.

UF and RO Systems

These systems provide ultra-pure treated water.great for reuse in processes or gardening.

PLC and SCADA Integration

Smart plants are efficient plants. With fully automated controls, you get real-time monitoring, fault detection, and remote access.

ETP Installation Process in Dairy Units

- Site Survey & Requirement Analysis

The first step is understanding the plant layout, daily wastewater load, and available footprint. - Design, Engineering & CustomizationNext comes CAD-based layout planning, equipment sizing, and process flow diagrams.tailored for dairy effluents.

- Fabrication & On-site Installation

Manufactured at Aquacaresee’s in-house facility, the plant is then installed on-site with minimal disruption. - Testing, Commissioning & Training

Their team tests every part before handover. They also train your staff for daily operations, backwashing, and chemical dosing.

Benefits of Installing ETP from Aquacaresee

- Full environmental compliance

- 85% water reuse potential

- Increase in corporate brand value

- Hassle-free operation with automation

- Rapid ROI through cost savings

Future Trends in Dairy Wastewater Treatment

The future of wastewater management in dairy plants is leaning heavily toward energy-efficient and zero-waste solutions. With climate change and water scarcity becoming global concerns, innovations like membrane bioreactors (MBRs), AI-driven water monitoring, and resource recovery systems are gaining traction. Aquacaresee is already investing in next-gen filtration and IoT-based monitoring tools, helping dairy units stay ahead of regulatory and sustainability curves.

Government Subsidies and Support for ETP Installation

The Indian government, through bodies like MSME Ministry, MPCB, and National Dairy Development Board (NDDB), provides financial subsidies and low-interest loans for industries adopting pollution control measures. Dairy units in Nashik can benefit from capital subsidies up to 50% for ETP installation, provided the system meets certified standards. Aquacaresee Pvt. Ltd. also assists its clients in the documentation and application process, helping them reduce initial capital burdens.

How to Request a Site Visit or Quotation from Aquacaresee

Getting started with Aquacaresee is easy. Just visit their website or call their Nashik team for a free site evaluation. After understanding your plant’s operations, effluent volume, and compliance needs, they’ll send you a detailed technical proposal and quotation. Their transparent, no-obligation process ensures you’re well-informed before committing. Plus, they offer AMC and operator training packages for long-term support.

Frequently Asked Questions (FAQ) :

Q1. What is the capacity range of ETPs offered by Aquacaresee for dairy plants?

Ans: They offer solutions from 5 KLD to 500 KLD, tailored to your load and operational needs.

Q2. Can treated water be reused in dairy plants?

Ans: Yes, after tertiary treatment like UF or RO, water can be reused for cleaning, gardening, and more.

Q3. How long does it take to install an ETP in Nashik?

Ans: Typically, 6–8 weeks depending on plant size and site conditions.

Q4. Is automation necessary for small dairy ETPs?

Ans: While not mandatory, automation ensures ease of operation and consistency in results.

Q5. Does Aquacaresee help with obtaining NOC or compliance certifications?

Ans: Absolutely! They assist in preparing reports, lab testing, and submitting documents to authorities

Get a Free Consultation from Aquacaresee

- Phone:+ 91 – 96532 47121 / + 91 – 98606 63150

- Email: marketing@aquacaresee.com

- Website: www.aquacaresee.com

Conclusion

If you’re running a dairy plant in or around Nashik, investing in an ETP is not just smart it’s essential. With Aquacaresee Pvt. Ltd., you’re choosing a partner that brings experience, innovation, and reliability to the table. From custom solutions to regulatory compliance, they’ve got your back just like they’ve had for the last 18+ years.